How does the QCI tolerance check for manual/external quantity value entry work?

SAP QCI conversion groups, as well as the MQCI conversion groups, support direct entry of quantity values from external systems, e.g. TAS systems.

The external values may have been calculated / determined in an unknown way, but are believed to be trustworthy and thus required in the SAP system as is. Once entered into the SAP system, they are compared with the SAP QCI / MQCI calculated results, which are defined by the SAP QCI/MQCI conversion group configuration – based on well defined measurement standards implementations defined in your BCS implementation project.

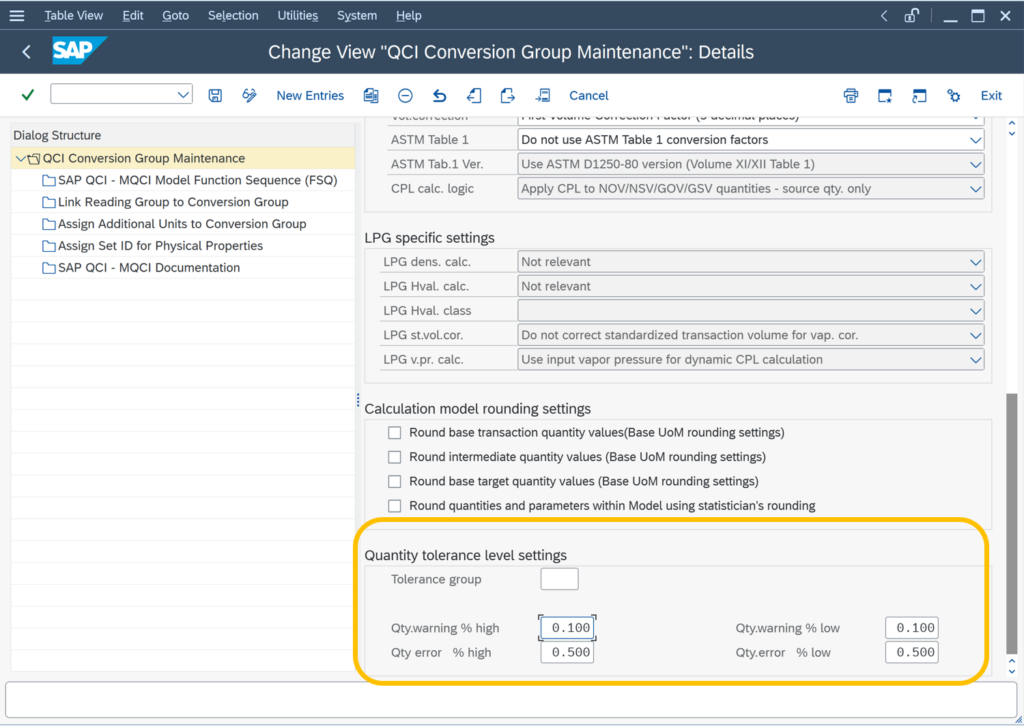

If deviations occur, the system checks that these deviations are within the limits defined in the conversion group, which is assigned to one or more materials in the SAP material master:

The QuantityWare template conversion group tolerances are set to 0.1% deviation, which triggers a warning message, if quantity value differences between externally passed and internally calculated values are below or above that limit and 0.5 % deviation, which triggers an error message, if quantity value differences between externally passed and internally calculated values are below or above that limit.

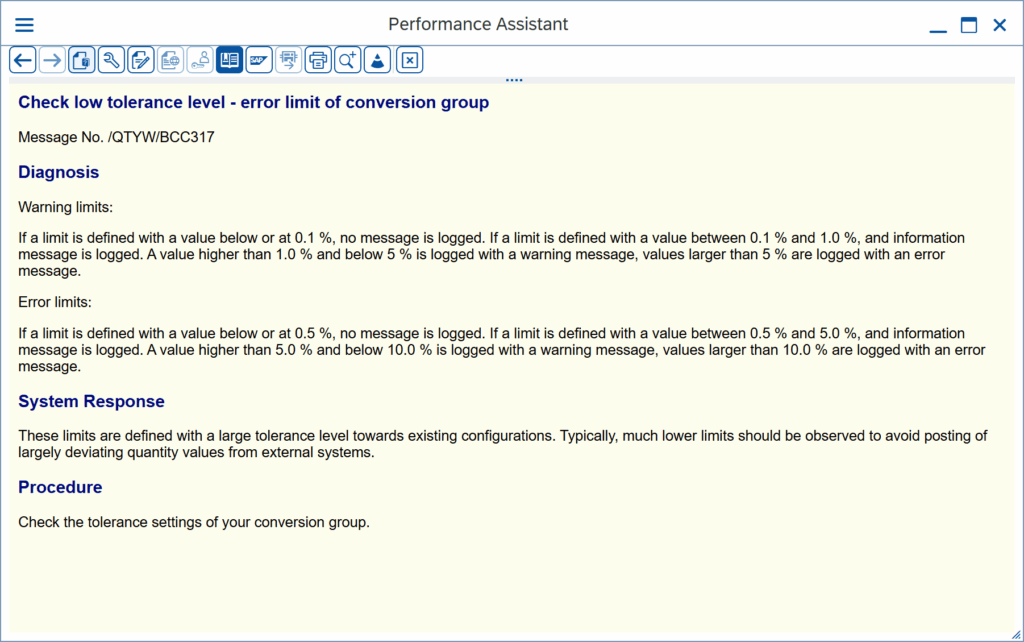

NOTE: These settings are lower – typically by a factor of 100 – when compared with the SAP QCI legacy settings (e.g. 534A, 534B, …) but are still considered to be larger than realistic limits in well designed productive system landscapes. This is documented in the messages that you receive when you execute the conversion group check with higher limits:

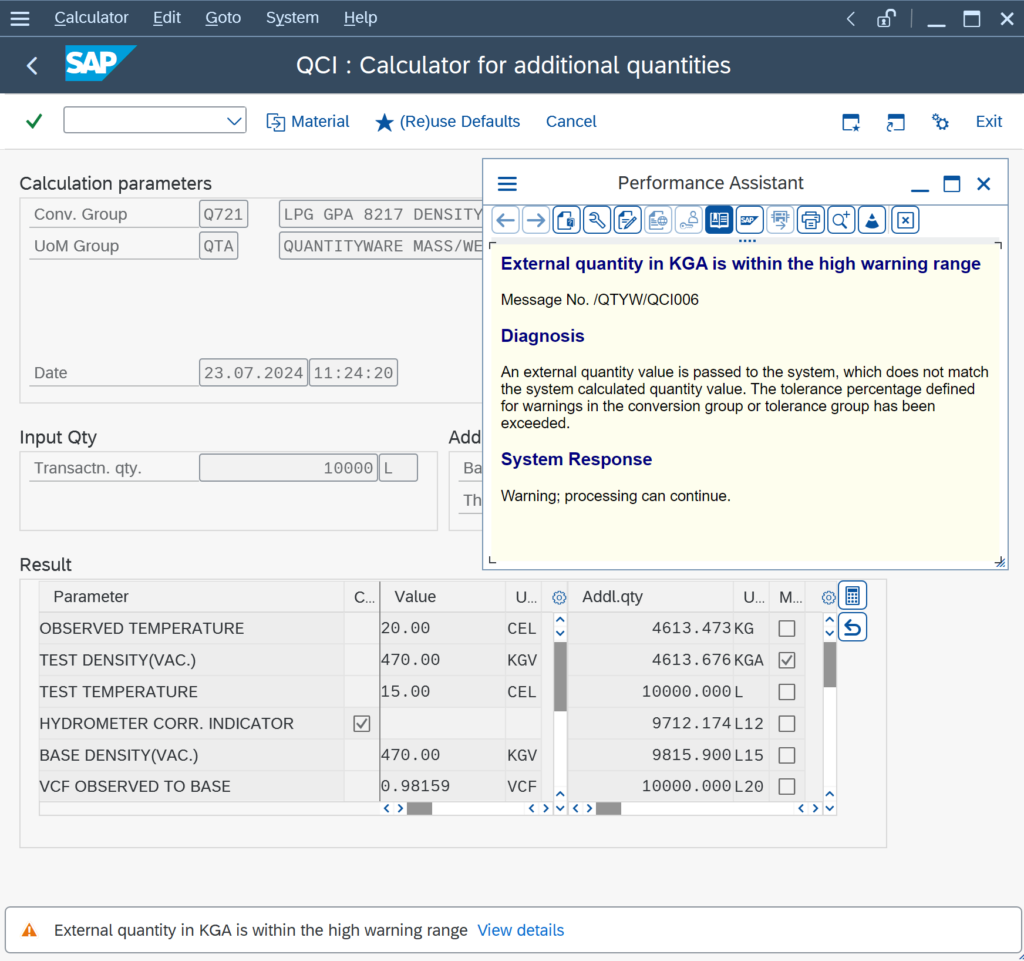

Example: Message issued when calculation results are deviating/manually changed:

Technically, these limits can be decreased or increased largely. QuantityWare MQCI conversion groups can also be configured to work with a tolerance group – see BCP Documentation Reference Manual – Chapter 6.11. for details.

Externally entered/passed values, that deviate from the validated SAP QCI / MQCI calculated values, are marked with an indicator (MANEN) in business documents.

Changes in the tolerance settings and final adjustments should be made by a QuantityWare Certified Consultant (QWCC). These settings are critical for a working gatekeeper functionality within your SAP system.

If you have assigned a conversion group to a material, where deviations between the externally calculated quantity values and the SAP calculated quantity values (SAP QCI or MQCI) are rather large, the fundamental questions are:

If large deviations need to be accepted for a few materials, this may require either an increase of the tolerance levels in the existing conversion group (affecting all materials assigned to that conversion group!) or a dedicated, newly configured conversion group for such materials, where – for whatever reason – a close match between the external and internal values cannot be achieved. Involvement of a QWCC is crucial.

The following messages are raised if tolerance levels are exceeded:

SAP QCI conversion groups:

O3 021 Manually-entered quantity in & is within the high-warning range

O3 022 Manually-entered quantity in & is outside the error range tolerance (low)

O3 023 Manually-entered quantity in & is outside the error range tolerance(high)

O3 024 Manually-entered quantity in & is within the low warning range

MQCI conversion groups:

/QTYW/QCI 004 External quantity in & is outside the error range (low)

/QTYW/QCI 005 External quantity in & is outside the error range (high)

/QTYW/QCI 006 External quantity in & is within the high warning range

/QTYW/QCI 007 External quantity in & is within the low warning range

Categories: BCS Messages FAQs | BCS Security & GRC FAQs | Oil & Gas Quantity Conversion Basics FAQs | SAP QCI General Configuration FAQs

Back to FAQs