How does the “air buoyancy indicator” influence a quantity conversion calculation?

The air buoyancy indicator concept is an SAP QCI legacy concept, based on DIN 51757, to support calculation of weights.

You define the air buoyancy “factor” in the material master, typically 1.1 ( kg/m³), as defined in DIN 51757. Then, if you set the indicator during business transaction processing, the SAP DIMID MASS UoM are calculated as weights ( the base density in air in kg/m³ is internally calculated by subtracting the 1.1 kg/m³ value defined in the material master from the base density in vacuo) .

If the indicator is not set, the SAP DIMID MASS UoM are calculated as masses.

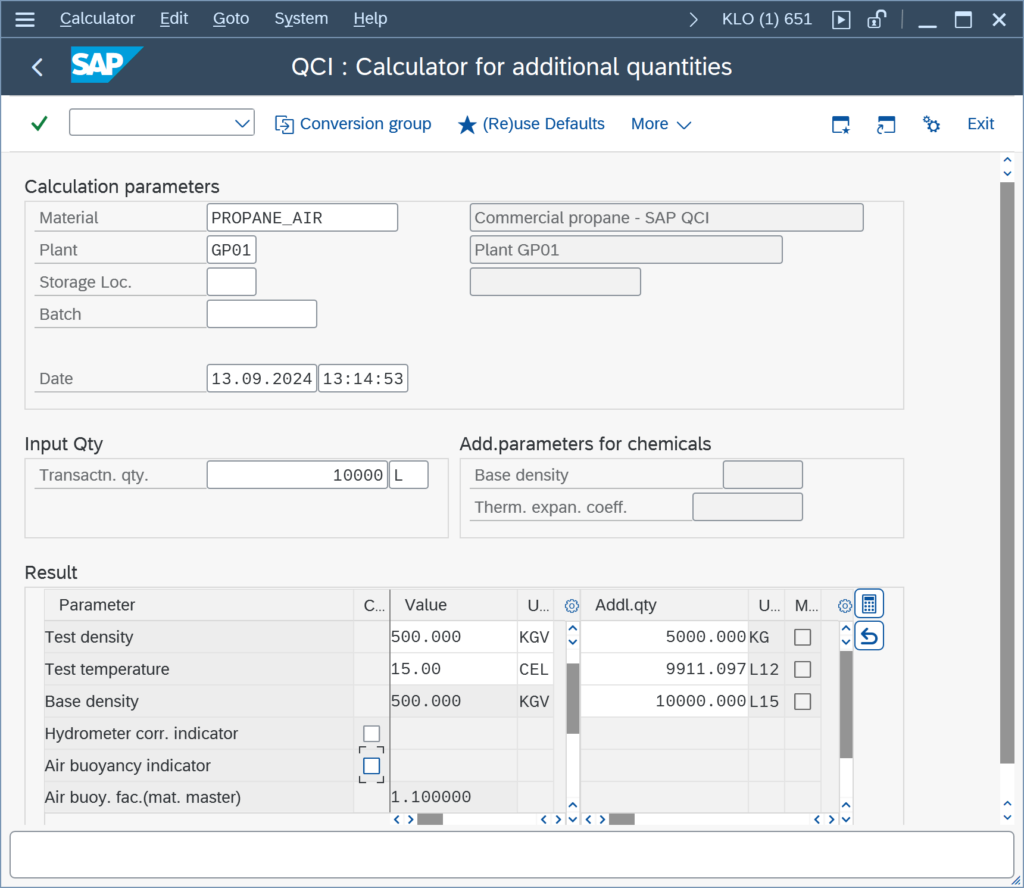

Example 01 – air buoyancy indicator not set:

10 000 L propane with a base density (in vacuo) at 15 °C of 500 kg/m³ are converted to a mass of 5 000 kg:

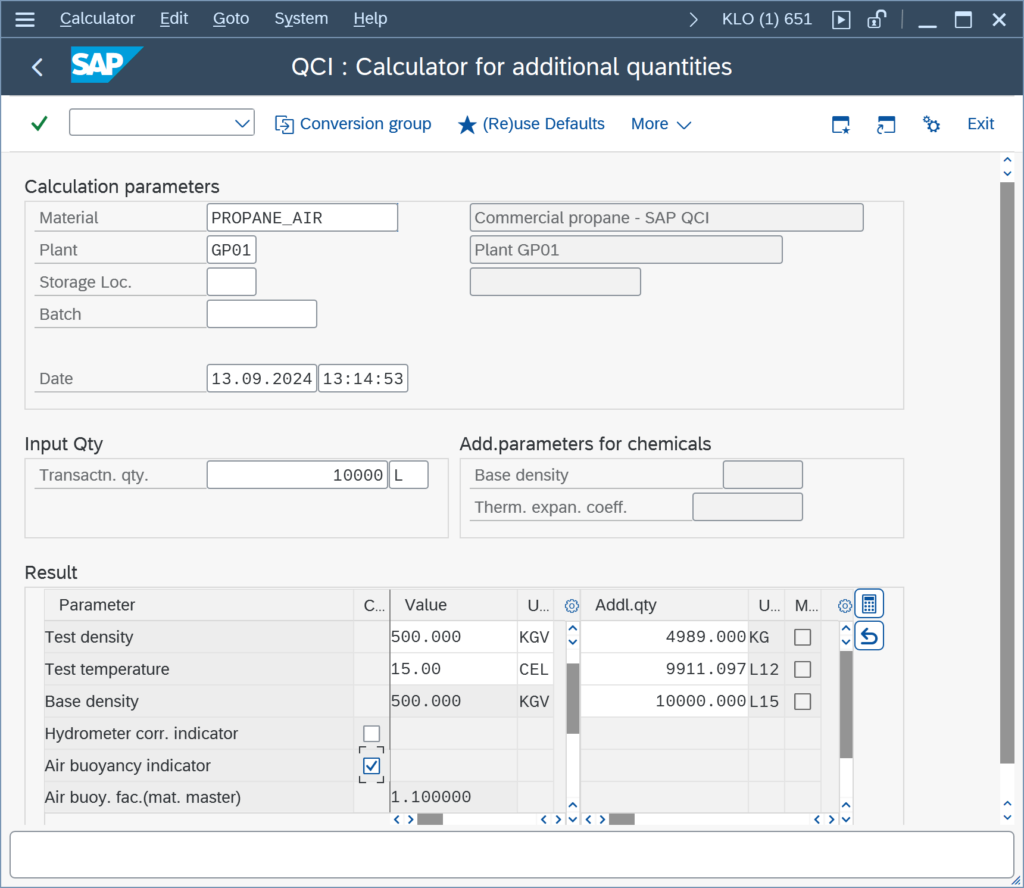

Example 02 – air buoyancy indicator set:

10 000 L propane with a base density (in vacuo) at 15 °C of 500 kg/m³ (and an internal base density in air at 15 °C of 498.9 kg/m³) are converted to a weight of 4 989 kg:

QuantityWare considers this to be a dangerous legacy concept, which may lead to mixing of stock levels of mass and weight UoM, if the air buoyancy indicator is not always set / always not set.

Also, this concept does not support ASTM D1250-80 mass to weight conversions of e.g. Table 8, Table 11, Table 26 … .

That is why MQCI conversion groups support parallel calculation of masses AND weights – see FAQ MASS WEIGHT for details.

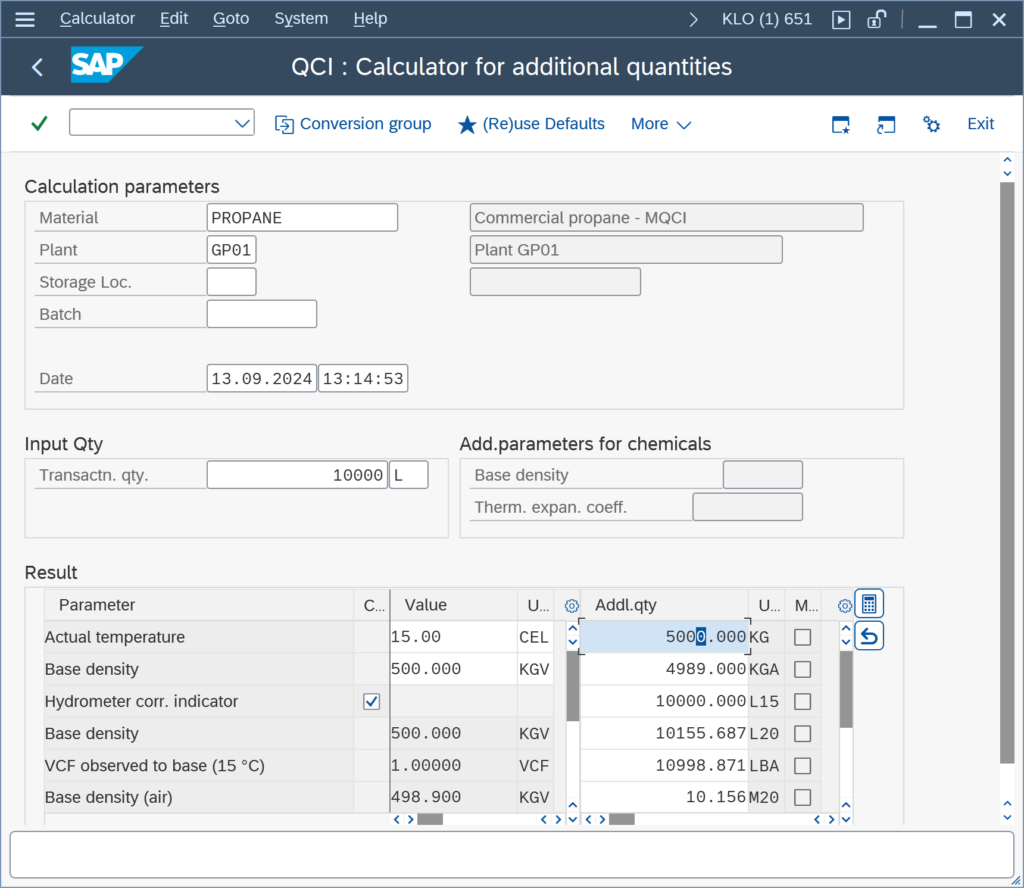

Example 03 – MQCI Conversion Groups – No air buoyancy indicator required:

10 000 L propane with a base density (in vacuo) at 15 °C of 500 kg/m³ and a base density in air at 15 °C of 498.9 kg/m³ are converted to be equal to 5 000 KG (kg – mass) and 4 989 KGA (kg – weight):

Here, no indicator is required since masses (e.g. KG) and weights (e.g. KGA) are calculated in parallel.

Note: Read the Mass Weight Switch FAQ for additional options.

Categories: SAP QCI General Configuration FAQs

Back to FAQs